1. Hoʻohui kēia mīkini paʻi flexo ʻano stack i kahi ʻōnaehana pretreatment corona hou e hoʻonui i ka ikehu ʻili o nā mea i ka manawa maoli, lanakila pololei i ka pilikia hoʻopili o nā substrates non-polar e like me PE, PP, a me ka foil metala, e hōʻoia i ka hoʻopili paʻa ʻana o ka ʻīnika i ka wā o ka paʻi wikiwiki, hoʻopau i nā pōʻino huna o ka de-inking a me ka stratification, a e noʻonoʻo i nā pono o ke kaiapuni a me ke kūpaʻa ʻoihana o ka paʻi flexographic.

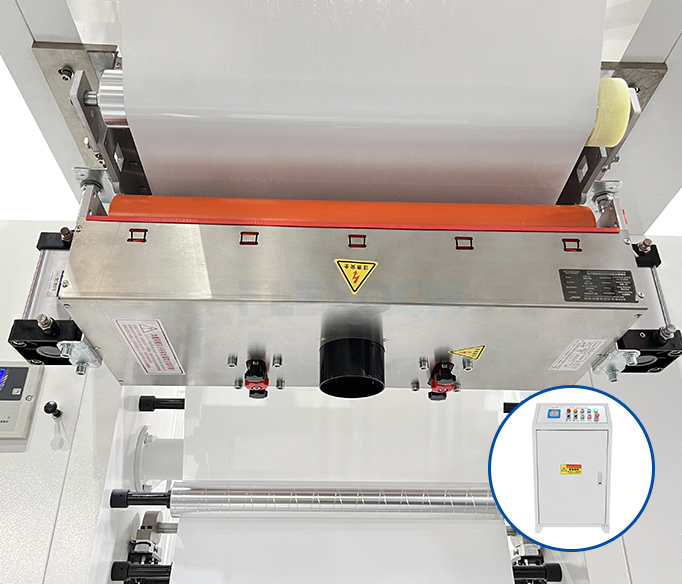

2. ʻO ka hoʻolālā modular o ka mīkini paʻi flexo ʻano stack he kūpono ia no nā hiʻohiʻona he nui, mai nā kiʻiʻoniʻoni papa meaʻai a hiki i ka ʻōpala hui lāʻau lapaʻau, mai nā ʻīnika aloha kaiapuni a hiki i ka paʻi kūikawā UV, a hiki ke pane koke. Mālama ka ʻōnaehana stacking compact i kahi mea kanu, ʻo ka ʻōnaehana hoʻopaʻa inoa mua akamai a me ka hoʻololi wikiwiki e hoʻopōkole i ka manawa hoʻololi kauoha, a hui pū ʻia me ka module hoʻonui corona kūloko, hiki iā ia ke hoʻokō maʻalahi i nā koi hana maikaʻi e like me nā lepili anti-counterfeiting a me nā uhi kiʻekiʻe.

3. Loaʻa i ka mīkini paʻi flexographic stack ka waiwai lōʻihi o ka hoʻokele kikowaena akamai. Nānā ka ʻōnaehana i ke kaʻina hana paʻi holoʻokoʻa i ka manawa maoli, hoʻomaikaʻi kūʻokoʻa i nā palena corona a me ke ʻano hana, a hui pū me ka ʻikepili kaʻina hana mōʻaukala ma ke ao e hōʻemi i nā kumukūʻai debugging a me ka hoʻonele ikehu. Hoʻoikaika i ka hoʻoholo ʻana me ka ʻikepili, kōkua i nā ʻoihana e hoʻokō i nā hoʻonui hana akamai ʻōmaʻomaʻo a hoʻomau i ke alakaʻi ʻana i ke ala paʻi pūʻolo.